Hi Earl;

Thank you and everyone else for chiming in. It's a great experience to learn from you all.

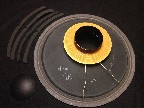

The driver and diaphragm in your picture look very nicely made. We used to alodine some of our aluminum products and it looked very much like that pic. Not saying it's not mag.

I read the sheet on the mag alloy and the process. I have never handled magnesium foil but would love to bend some around and see what it feels like.

HI Ken;

One of those Be diaphragms is what I handled at JBL. Literally light as a feather, it just floats to the ground when dropped.

Hi ivica;

When the costs of manufacturing, packaging, warehousing, distribution, customer service and warranty are factored in, 400% over cost of manufacture is a fairly standard minimum retail sales benchmark, at least in my industry.

All the best!

Barry.

Reply With Quote

Reply With Quote