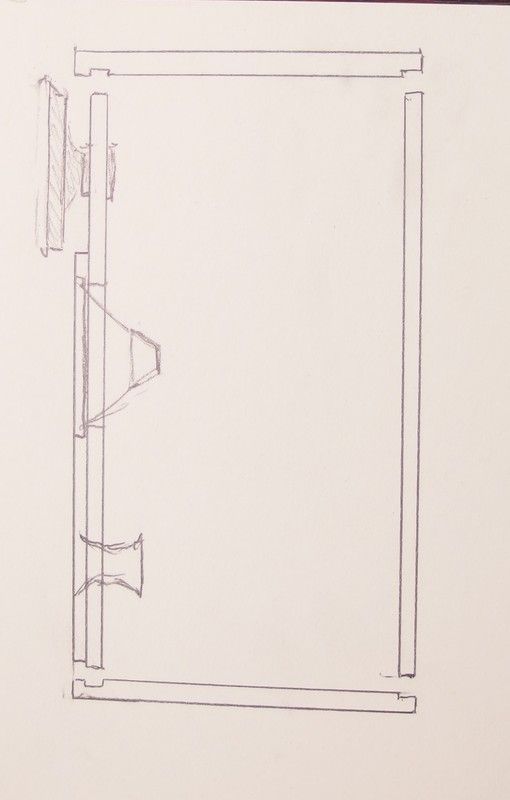

1: Have some idea of what you're doing

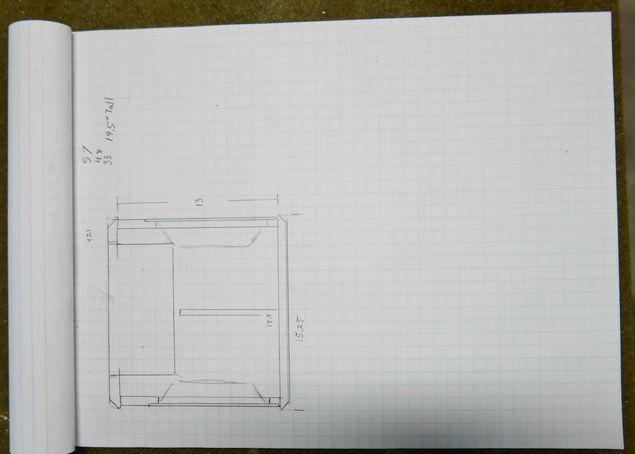

It sounds a bit basic, but I for one have to constantly remind myself to flesh out a plan before I start cutting...the point of this thread is help with that in fact.

Google SketchUp is useful if you're intelligent or graph paper will do if hopelessly daft.

Here's what I use.

It's just a plan for a generic subwoofer, but you get the idea.

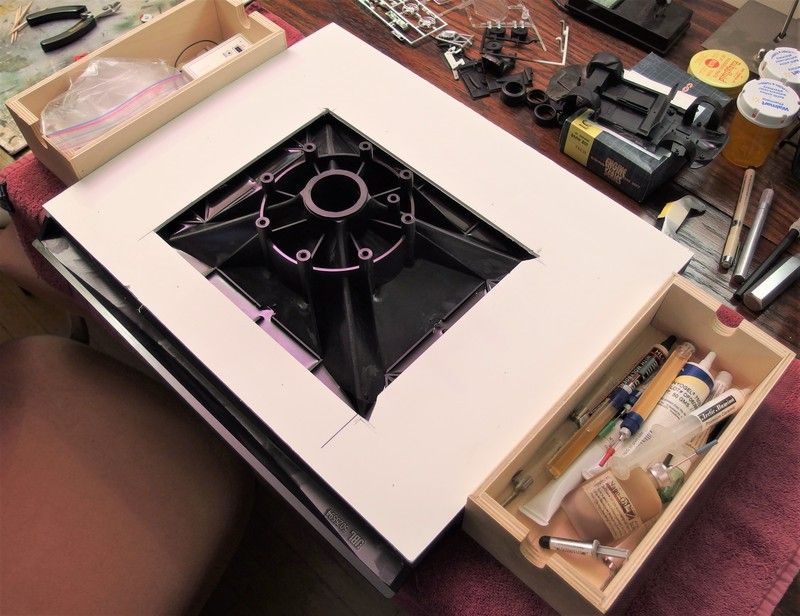

2: Layout gear

The ability to measure & mark off what you want to cut or drill is a big deal. Maybe I'm just paranoid, but I hate guesswork so I got the nicest squares I could afford.

The iron block with many holes is a drill guide to keep the bit perpendicular when hand drilling and the auto punch makes a nice dent to prevent the bit from walking.

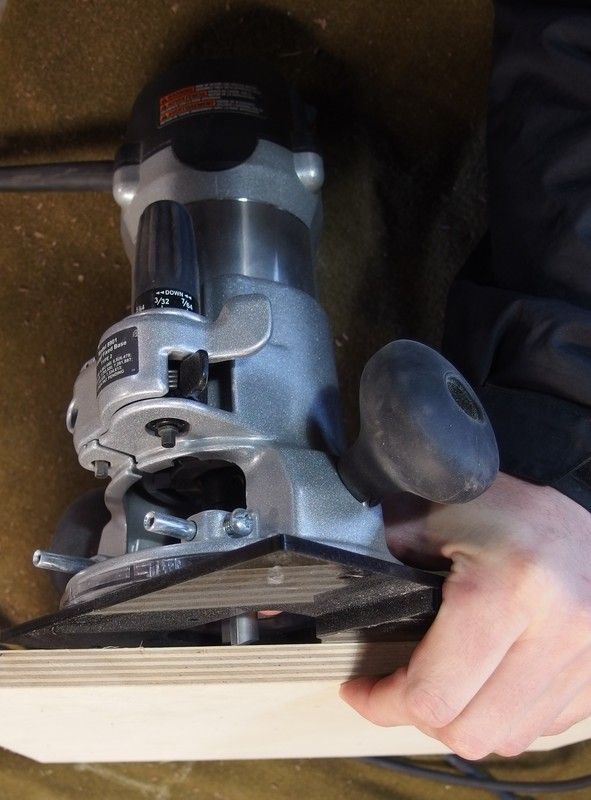

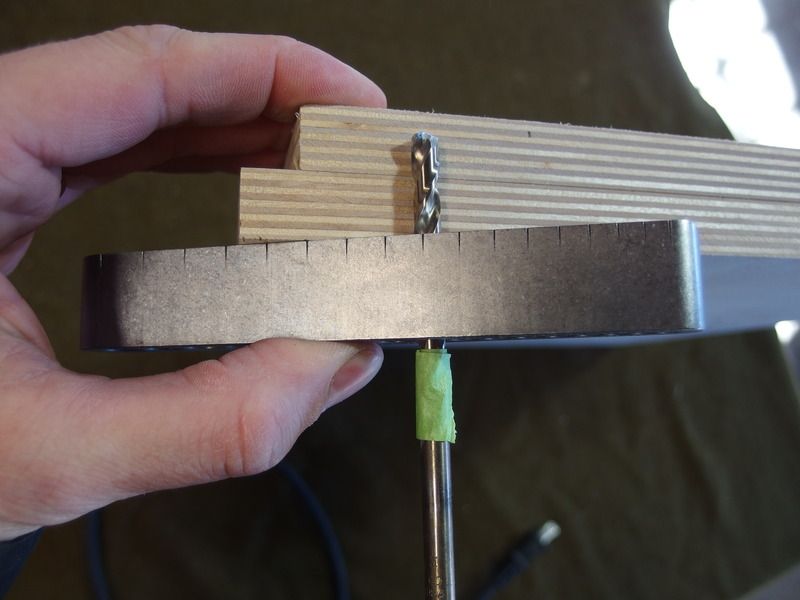

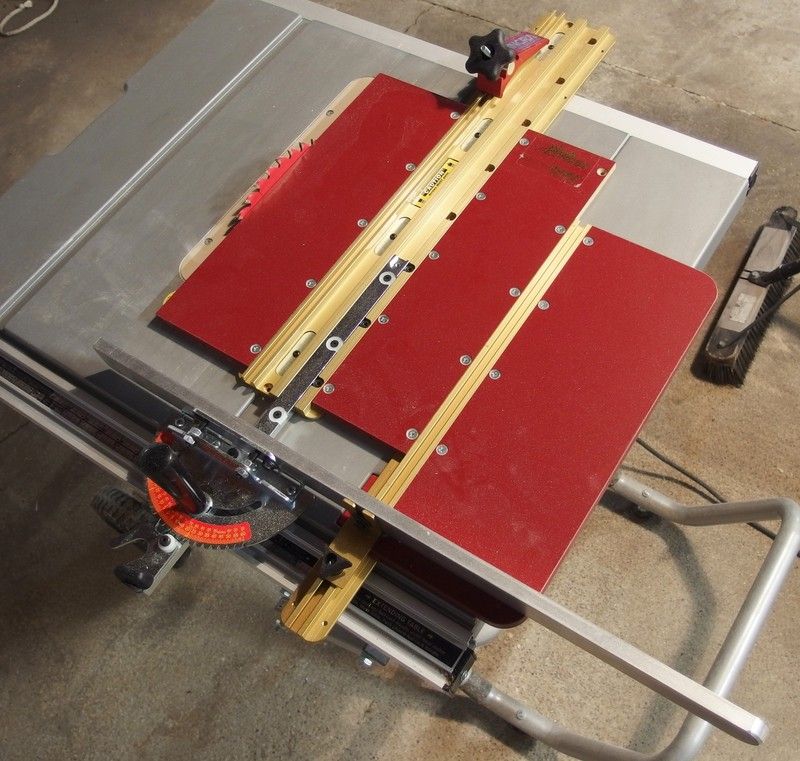

3: Pursue Precision

Precision of this level requires more than good hand/eye coordination. You've got to build or buy tools & accessories that won't allow you to mess things up just because you're a slowly dying bag of flesh.

This amazing device is the CRB7. If you don't have room for router table, it's the thing to have as it allows your handheld router to be much more useful than I ever thought possible...more on this later.

This heap of kludge is an Incra brand sled. I added that three foot long chunk of aluminum to the miter to help keep things straight when handling the large sheets for this project. The clamp at the forward end helps a lot too.

Stay tuned...

Reply With Quote

Reply With Quote