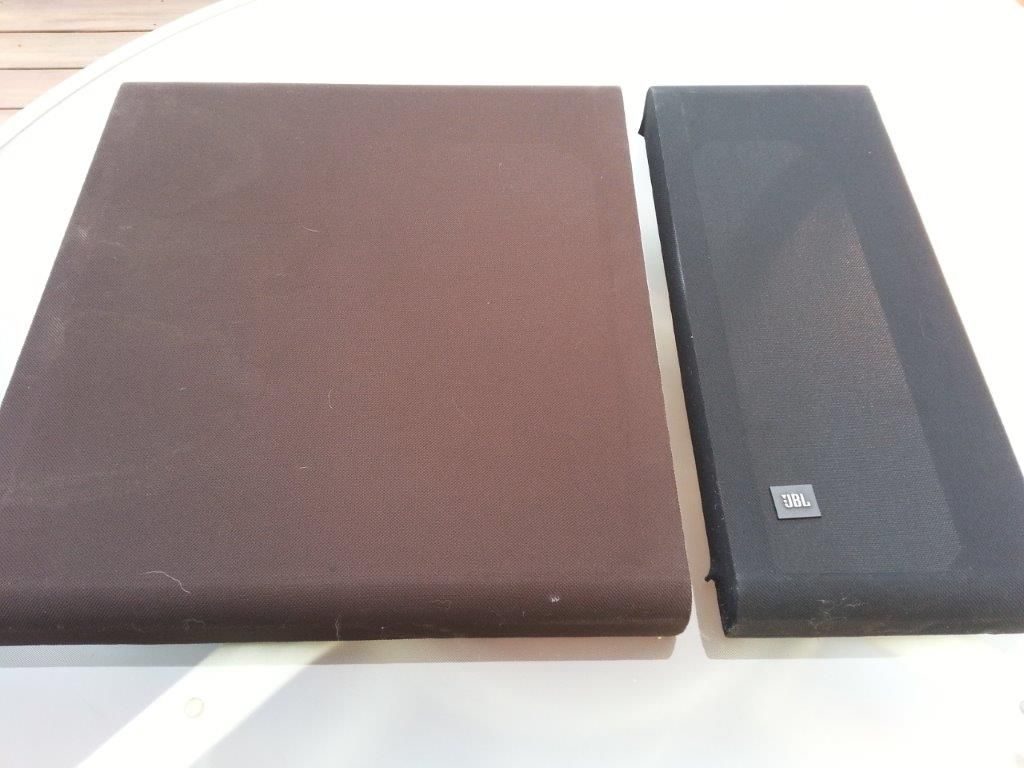

Good tips Joseph Smith. I`m afraid I got a little ahead of myself with this restoration which, incidentally is moving right along very nicely so far. I refinished the baffle

before extracting the broken peg

. I now run the risk of marring the surface when I do get around to extracting it, but that wont happen before I source a replacement.

The Ebay pegs sure look good but a single one will set me back more than $26 by the time it gets here so I`m trying to source a used one elsewhere if at all possible.

Reply With Quote

Reply With Quote

, JBL Fan mech986 says

, JBL Fan mech986 says

. I now run the risk of marring the surface when I do get around to extracting it, but that wont happen before I source a replacement.

. I now run the risk of marring the surface when I do get around to extracting it, but that wont happen before I source a replacement.