I wouldn't buy the Eminence networks . There's no telling how they will interact with your Altec components .

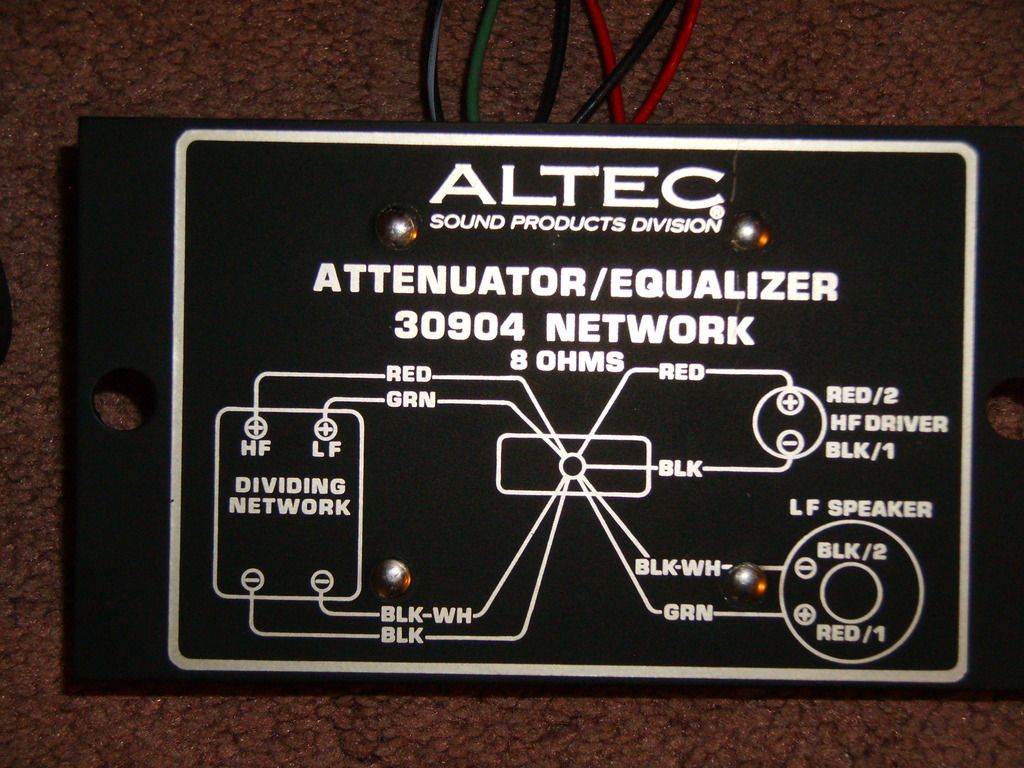

All-n-all, I believe you are best to buy ( via eBay ) a pair of N501-8a's ( if the lower x-over point is where you want to start ) or N801 or N809's ( for the higher 800hz point ) and then add the mid-range suppression circuitry ( 30903/4 ).

The two models seem to average $100.00 a piece ( judging from past sales ) . If they don't happen to work with your components they can at least be easily tossed back on the Bay to recapture most of your investment.

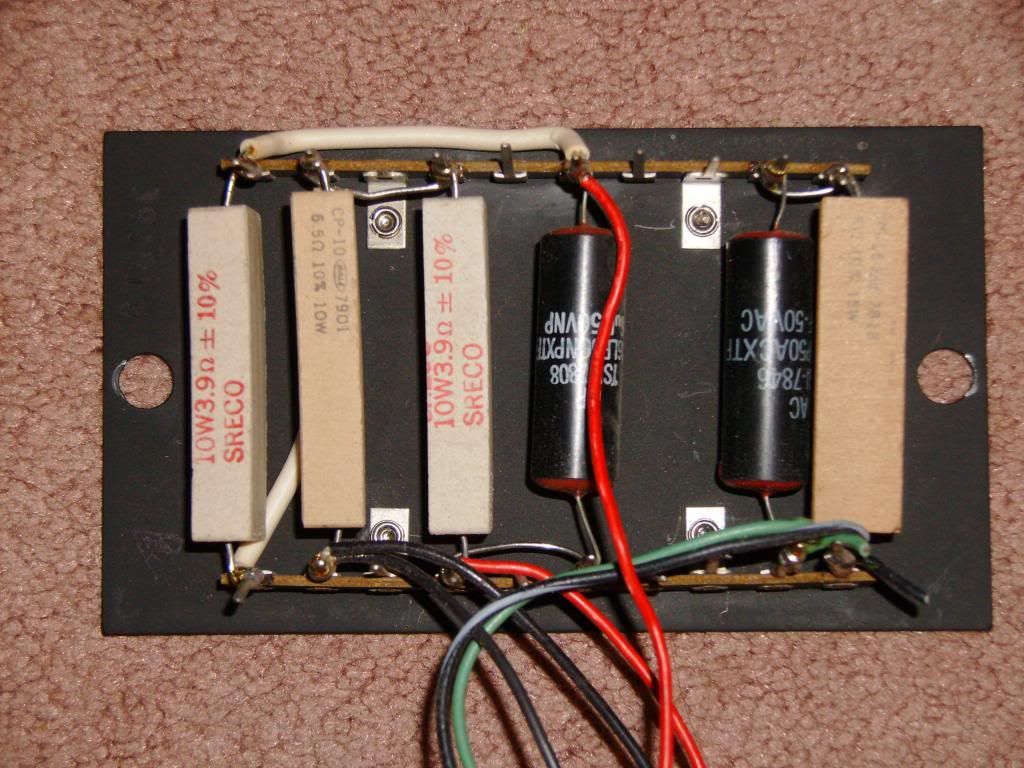

Making your own is slightly more affordable ( at around $80. to 90. ea ) using components from Parts Express .

- Also, ( fwiw ) the values I posted don't really come with a guaranteed certificate of provenance / though these questions of the accuracy of the LC values, could ( & should ) be researched .

- Here's

one older thread that's quite interesting

- And

Another !

Reply With Quote

Reply With Quote

.Unfortunately ! People weren't able to post at all !

.Unfortunately ! People weren't able to post at all !

"James B. Lansing" = Lansing Manufacturing ~ Altec Lansing ~ JBL

"James B. Lansing" = Lansing Manufacturing ~ Altec Lansing ~ JBL