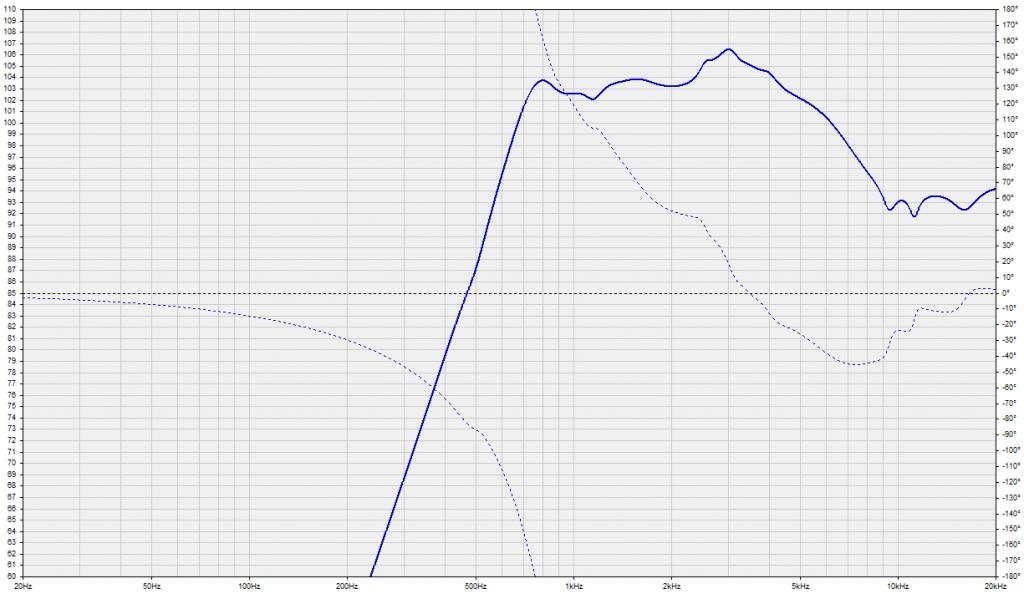

I did a quick shot of the 476Mg versus the D2430K on the M2 waveguide. I needed the impedance curves so I figured I'd collect some SPL curves at the same time.

I did a quick shot of the 476Mg versus the D2430K on the M2 waveguide. I needed the impedance curves so I figured I'd collect some SPL curves at the same time.

Hi 4313b,

From the text below the graph it looks like a very long time window Is that correct?

It also seems like Mg is falling off reasonably early and showing a similar pattern as the Be. That should be just fine with a DSP but given the difference betwee the drivers the correction file will need to be rather different.

Excellent info, thank you

Kind reargs

//RoB

The solution to the problem changes the problem.

-And always remember that all of your equipment was made by the lowest bidder

Right, I didn't gate the posted curves above nor did I measure them outside (raining) like I usually do. I didn't like how the gating affected the response around 500 to 1kHz. Usually I use tail correction in LEAP instead. For example, in this instance I would use tail correction below approximately 300 to 400 Hz.

I'll do the SPL curves that I will end up using outside some night soon. It appears that the 476Mg won't require nearly as much compensation on the top end, just like GT theorized.

Yep and that is the main thing one can take away from this quick set of graphs, the compensation filter for both drivers would be quite different.

Yeah, I suppose I could mark off a spot at 30 degrees off axis.

Sorry to be a dolt... (&thanks for the plots):

Mg is green?

Less compensation meaning less complicated vs D2?

(or have I got this upside down).

D2430k must be the green curve.

For comparison here is, with the same scale, the inverse of the EQ applied by the crown and passive network to make the D2430k flat (on average in the listening window).

This should be a fair representation of the natural response of the D2430K on the M2 waveguide.

You got a keen eye Thomas! It was actually done by forum member hlaari. Without it mounting would be utter pain. Now it is just fiddly

One question: I'm about to mount the WG to the baffle.

Two options: Tap the plastic with m5 and use bolts, or glue threaded rod in the hole?

I believe the plastic for flange mounting strong enough for supporting 2450sl so I will not brace the compression driver. Crazy?

Another thing: My wife waits eagerly to see me mounting the waveguide from the back. She this it's going to be quite entertaining with me halfway through the baffle hole and a lot of x rated language.

Kind of regret I did not build an access hatch on the back...

It is painful indeed, especially when the nut gets magnetized...

The easiest way I found is to maintain a distance between the driver and the waveguide so that the threaded rod only exceed a tiny bit over the adapter.

That way you only have to get the nut above the hole and gently turn it while it stays nicely flat...

Still cumbersome, to say the least.

I did a mix of the above: I used M6 threaded rods for mounting the waveguide to some metal brackets (no real baffle for now) with wing nuts.Two options: Tap the plastic with m5 and use bolts, or glue threaded rod in the hole?

I drilled the hols with a 5mm drill, but it is probably not necessary (Rob did not for example) as the holes are already 4.7mm.

Wing nuts are a good option if access is difficult.

Yes. I am not liking the looks of the 476Mg. I played around with the data - gating, smoothing, etc and the D2430K looks fine, 476Mg not so much.

I'll measure the other 476Mg at the same time I redo the measurements outside and determine if they need to be opened up for inspection.

I forgot to post which was which. D2430K is green. I wasn't all that excited about the results anyway. I primarily just needed the impedance curves for the time being and shot the SPL curves just because (in the living room on the floor, waveguides face up towards the ceiling).

Yes, the hole spacing proved difficult to measure properly is quite a bit off on mines so they are overzized... Blutack will seal it all up in the end

By the way, tapping for M5 direct went smoothly. Just finished it

Thanks for the tip on wing nuts Pos. that's what I will do

Yes M5 is easy to drill as you are supposed to drill a 4.2mm hole and the existing holes are 4.7mm IIRC.

That means that the grip will not be as good as the fillet will not be as deep as it is supposed to.

As long as you don't pull perpendicularly to the waveguide plan everything should be fine :P

I went for M6 for the mounting holes, which calls for a 5mm pre drilling, and used M5 for mounting the drivers because I wanted to keep as much material as possible there.

Hello 4313b

Here is a passive compensation voltage drive for M2 waveguide with 476mg It looked pretty good with my pair. You have a issue with the drivers?? Simulated on axis with network and schematic.

Rob

"I could be arguing in my spare time"

There are currently 1 users browsing this thread. (0 members and 1 guests)