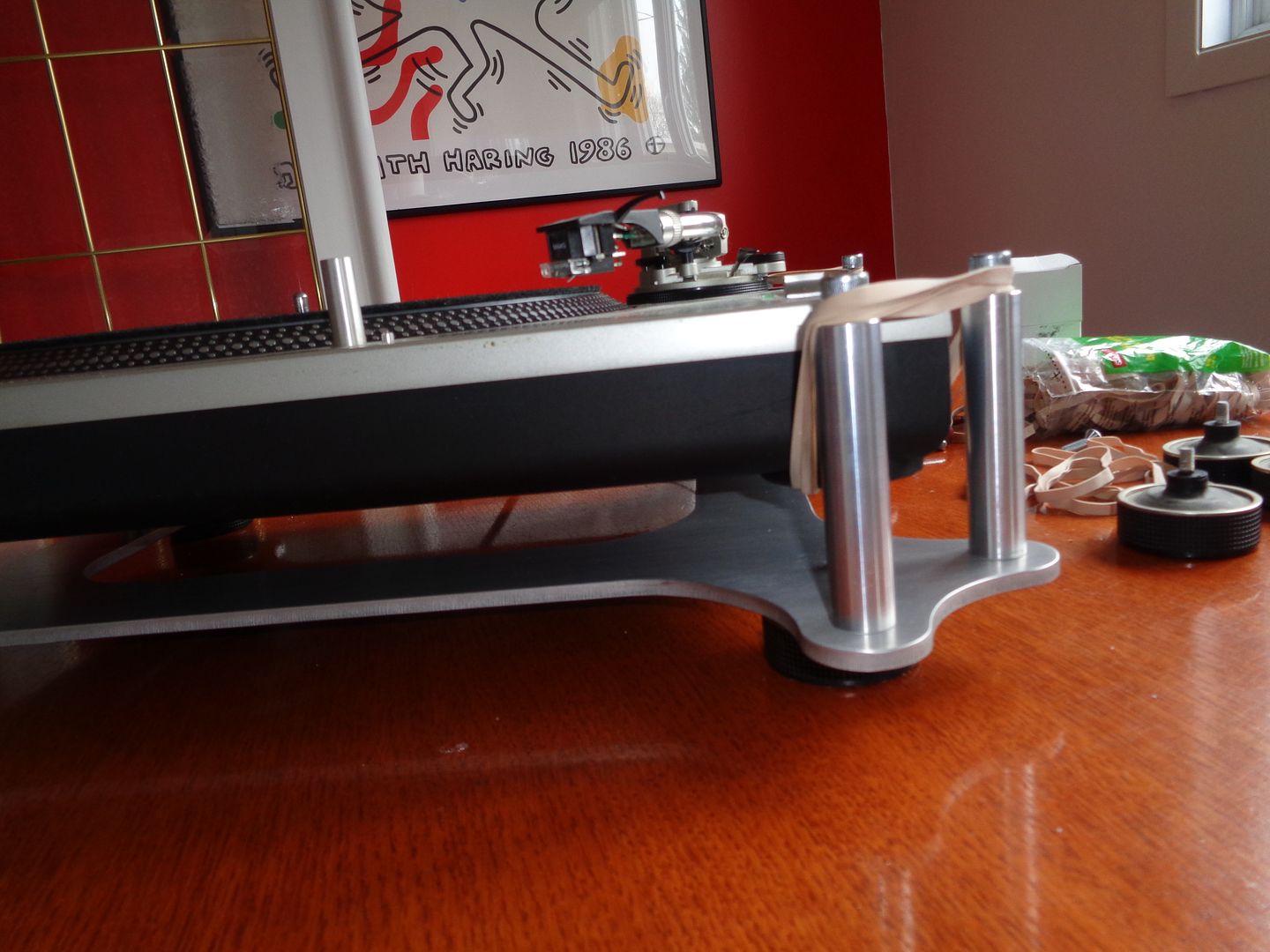

Two weeks ago, I was at a friend's place and we mixed some music for his MixCloud channel. When I listened to it back at home, and with the heavy sub bass I have, I couldn't help notice all the thumping in the background. Yup. The needle was catching people walking around the room. Soft floor in an old appartment. So, I checked for some old drafts I did years ago. Added a few notes and sent the blueprint into production. Here's what I ended with. The basic idea is to decouple the Technics SL1200 from floor vibrations by using rubber bands. exactly what you could find in clubs and discos back in the 1970s and 1980s. I made a pair for my friend and another for myself as prototypes. I will spend some time experimenting with rubber bands, positionning and weight distribution. But at least, we can do some mixes at my buddy's place without having to care how heavy we walk.

Reply With Quote

Reply With Quote