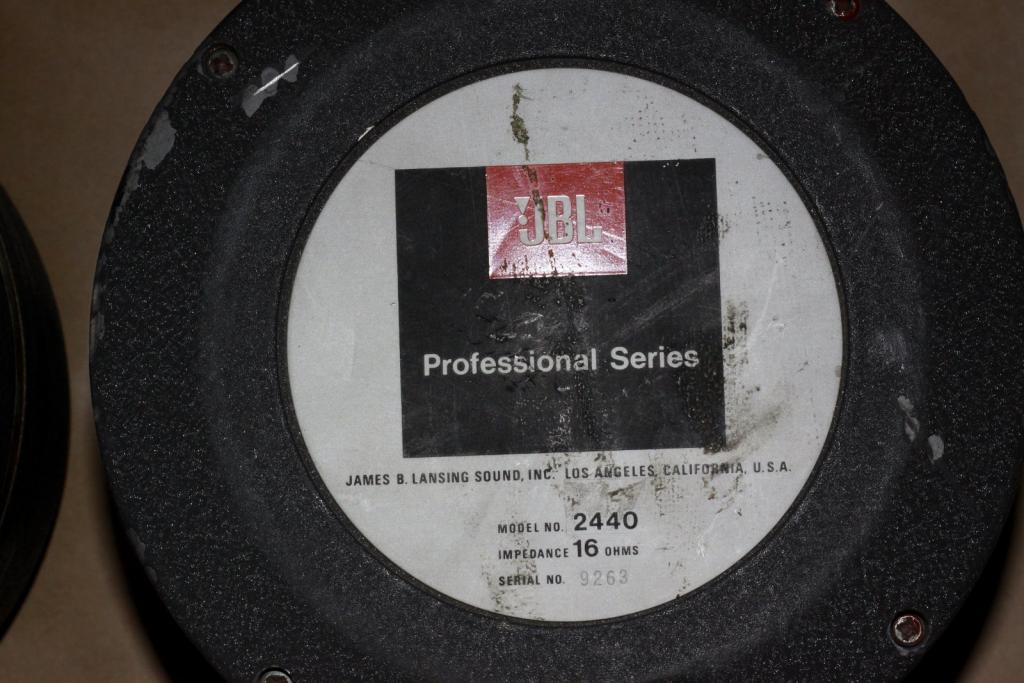

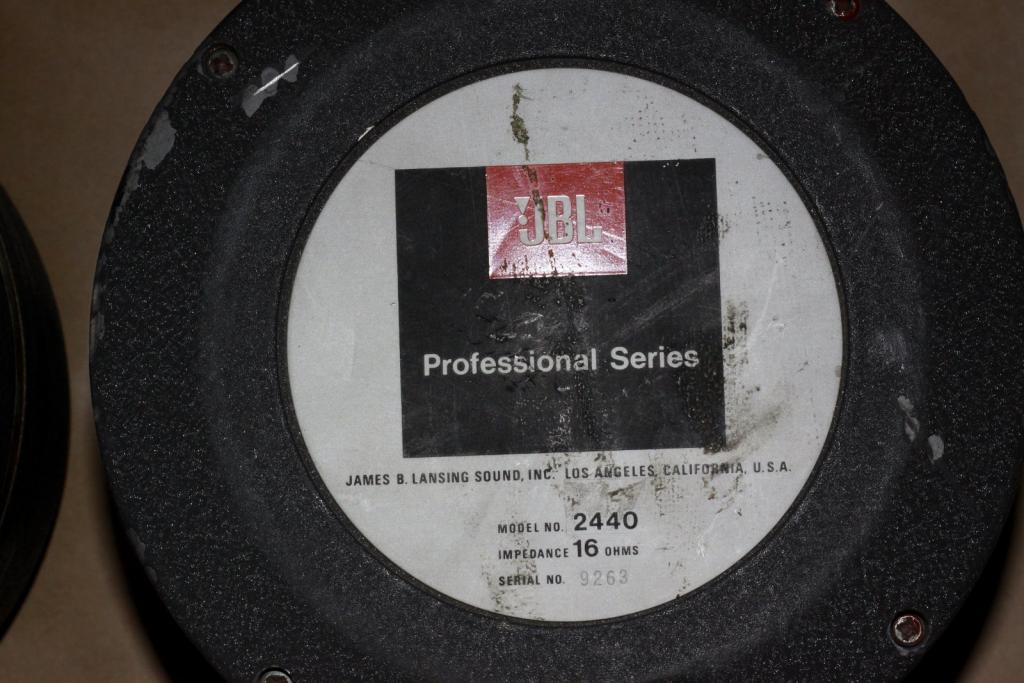

I recently bought a pair of worn 2440 which I intend to refurbish. This is the first time i do this, so some advice will be appreciated.

I recently bought a pair of worn 2440 which I intend to refurbish. This is the first time i do this, so some advice will be appreciated.

I believe the diaphragm is ok, this is a 2441 dia right?

First thing to do is to remove the diaphragm. For this I need a titanium (non magnetic) screwdriver.

Next thing is to have the drivers demagnitized. Then I can disassemble them. Before buying any spare parts I will check that the magnets are not broken.

They do look like 2441 diaphragms - definitely not 2240's, which have the half-roll surround. Before you go any farther, do you have a remedy for the cracked throats? I have no experience with these drivers, but I thought a cracked throat meant game over, driver dead. I'm sure the Pro guys here can chime in, but I don't think even the factory would touch these. Hope I'm wrong

If you have a shop that can demag them, get the throats from JBL and remag you are back in business. JBL used to fix them. Now?? Do they have throats for them??but I thought a cracked throat meant game over, driver dead. I'm sure the Pro guys here can chime in, but I don't think even the factory would touch these. Hope I'm wrong

Rob

"I could be arguing in my spare time"

More10

I'm pretty sure a good machinist could make new throats if the dimensions are around ... I can't see

as a really expensive thing to do .... If your stuck PM Guido for the name of that company in Berlin that does all this sort of thing ....

Rich

PS stay out of the bar and save for the Be

Well, if I can´t get new throats from JBL, a friend of mine can shurely make them. With or without factory dimensions. He has got a CNC lathe.

I had a pair of 2441s shipped to me and both throats were cracked. But they were made of plastic. Not sure is that would be easier or tougher to fabricate than metal throats. But you have the option to make them from just about anything.

Non-magnetic tools = VERY positive.

Having a cracked throat is not the end of the world and having them demagnetized isn't necessary either.

I've been told that having a cracked throat is a more typical rule of thumb but it's very nice if you can locate a un-cracked pair.

I cut a piece of UL rated aluminum foil (HVAC) tape (the thick stuff) and lined my cracked throat with it after cleaning out the broke plastic fragment pieces.

As for having them re-magnetictized, Great Plains will be happy to help (but most likely it's a wasted effort).

I did make some changes to the diaphragm cap after the typical clean-up and paint. I located some 1/2" wool mating, cut and glued into place it does a great job of whatever that foam material was supposed to accomplish.

After it was all said and done I ended up using a Radian Diaphragm instead of the OEM JBL's in a three way KHorn

crossed over a little higher than typical to unload the 2404H's and I have no complaints with the results.

And please note; I'm not a pro CD repair expert.

And my 2482's sound just fine. Thank You.

But I did have some nice long telephone conversations with several people that were.

The drivers are almost done now, thanks to my friend Peter who owns the lathe. Some pictures:

Using a large lathe to center the pole plate.

Outside was already done when I joined.

Drilling the inside

Peter working at the lathe

Mach3 CNC application

Inside being machined

Polishing the inside.

Throat finished.

No need for small tolerances :-)

All parts of a driver (except back chamber)

Details of each piece

There are currently 1 users browsing this thread. (0 members and 1 guests)