Just a quick question...

When I go to build my Usher D2 or JBL K2 "clones", I may want to try building a pair of Smith Horns for them just for fun. I'm thinking that because that design is much thinner than my Altec 511B's, the Smith's will allow the dual 15's to be closer together.

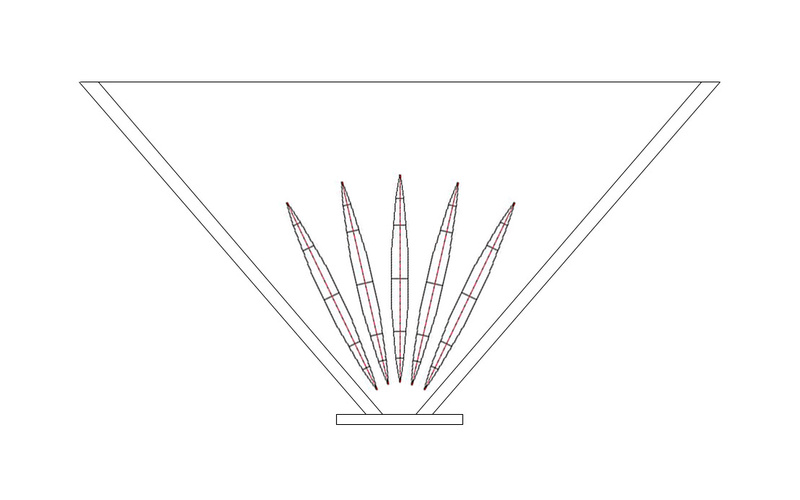

What I'm thinking about doing is have the Smith horn extend all the way from the front to the back of the speakers. This would have the Altec 902-8B drivers just past the rear of the bass enclosures, allowing the 15's that much closer together. Also, this horn would be over-built to support the weight of the upper bass enclosure as it would NOT have an enclosure of its own.

Now on top of that (this is where the question comes in), I thought that I could have the front of the horn perfectly flat and even with the front of the bass enclosures, instead of having them rounded in the front like traditional Smith horns and sticking out past the enclosures.

Would this be alright to do or is there a reason why the front of the Smith's are rounded?

Many thanks in advance!

Reply With Quote

Reply With Quote